I am part of the GeoData & Information Management (GDIM) department and as a member of the Science team, I contribute on projects necessitating Machine learning, AI, or big data processing tools crafted to challenging problems.

As an RSE at NLeSC I collaborated with researchers to develop software tools that enhance their research.

I am part of the Natural Sciences section and team Nabla \( \nabla \) working on projects involving Machine Learning and materials science.

Projects I have contributed to:

- GrainLearning: Neural networks as surrogates for simulation parameters inference.

- OnSET: Improving software practices for an efficient and robust open-source modelling platform for research on Energy Transition applications.

- DeepMolGen: Exploring generative AI tools for molecule generation with optimal properties.

- DEEPDIP: Enhance ML aided models with differentiable programming in Julia.

At

GRASP (Group of Research and Application in Statistical Physics), I was part of

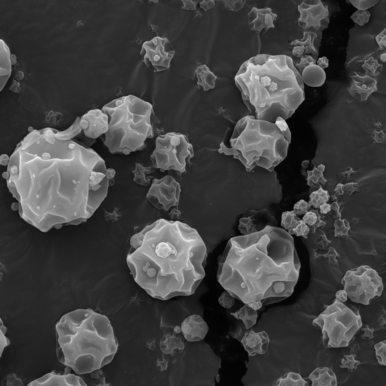

AEROPERF a multidisciplinary team focusing on the development and optimization of inhalation powders. These powders were engineered for effective pulmonary drug delivery, ensuring deep and homogeneous distribution in the lungs. My role involved the physical characterization of these spray-dried powders, specifically examining their agglomeration to improve flowability. Additionally, I conducted experiments and simulations on air fluidized beds, contributing to a deeper understanding of physical mechanisms crucial in various industrial applications.

My activities at the Laboratory of Mechanics and Civil Engineering (LMGC) included:

- In collaboration with INRAE, SupAgro supervise a Master student on experiments on grinding of a granular material.

- Research on effects of particle shape on the flow and breakage of granular materials.

- Teaching tasks included laboratory of materials and civil engineering.

Doctoral Researcher

-

CEASeptember 2016 - October 2019

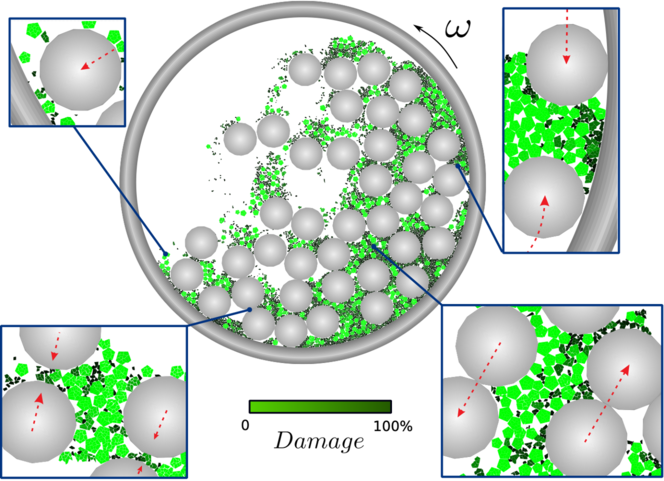

Modelling and characterizing granular flows in rotating drums and to elucidate the mechanisms of particle grinding across scales. By means of particle dynamics simulations and a breakage model involving the tessellation of particles and a dynamic debonding criterion based on fracture mechanics, I investigated single-particle impacts, the properties of granular flows in the cascading regime in a rotating drum as a function of system parameters, the effect of the size and amount of grinding media on the grinding process, and the evolution of particle breakage in flows of breakable particles.